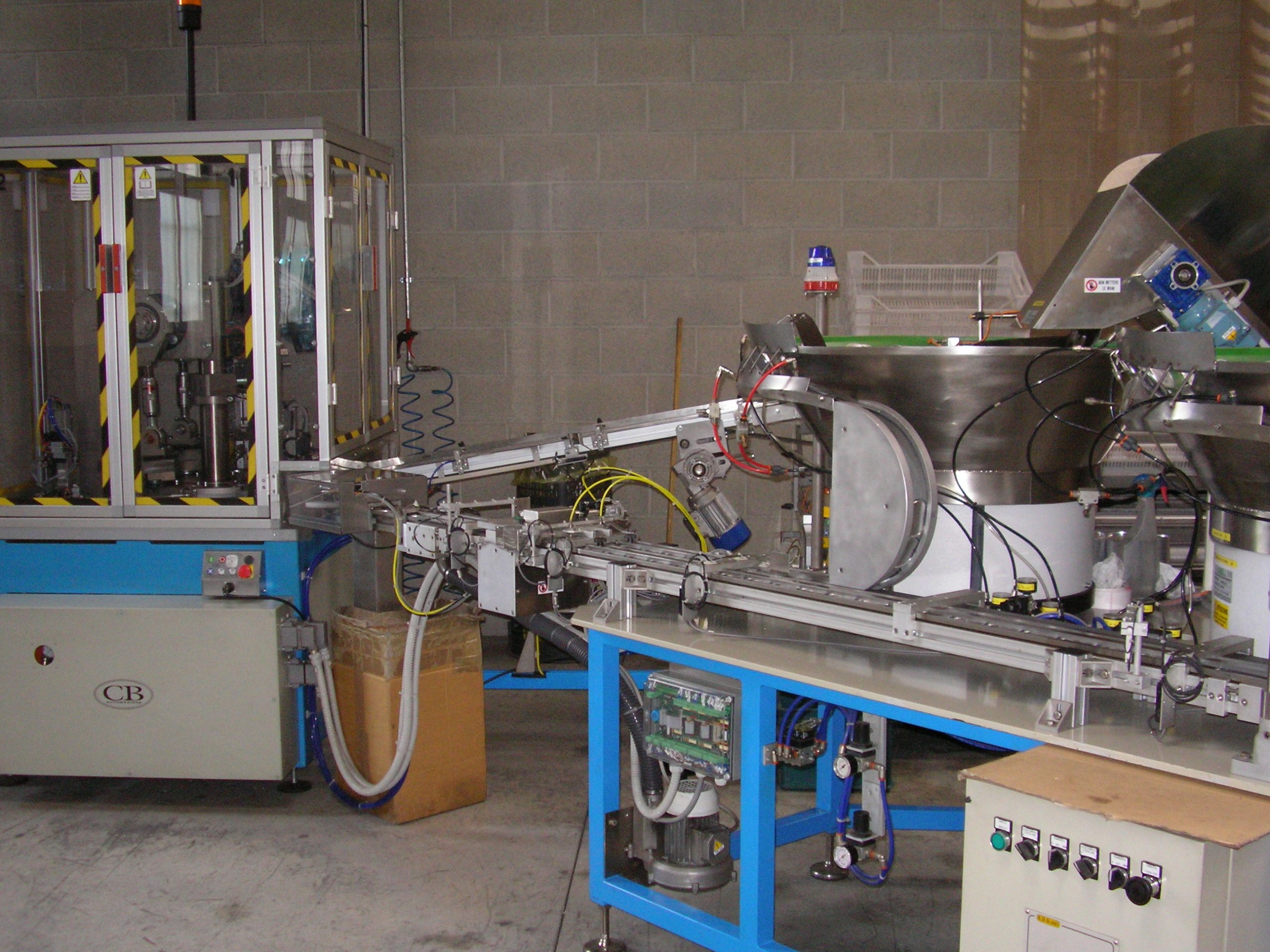

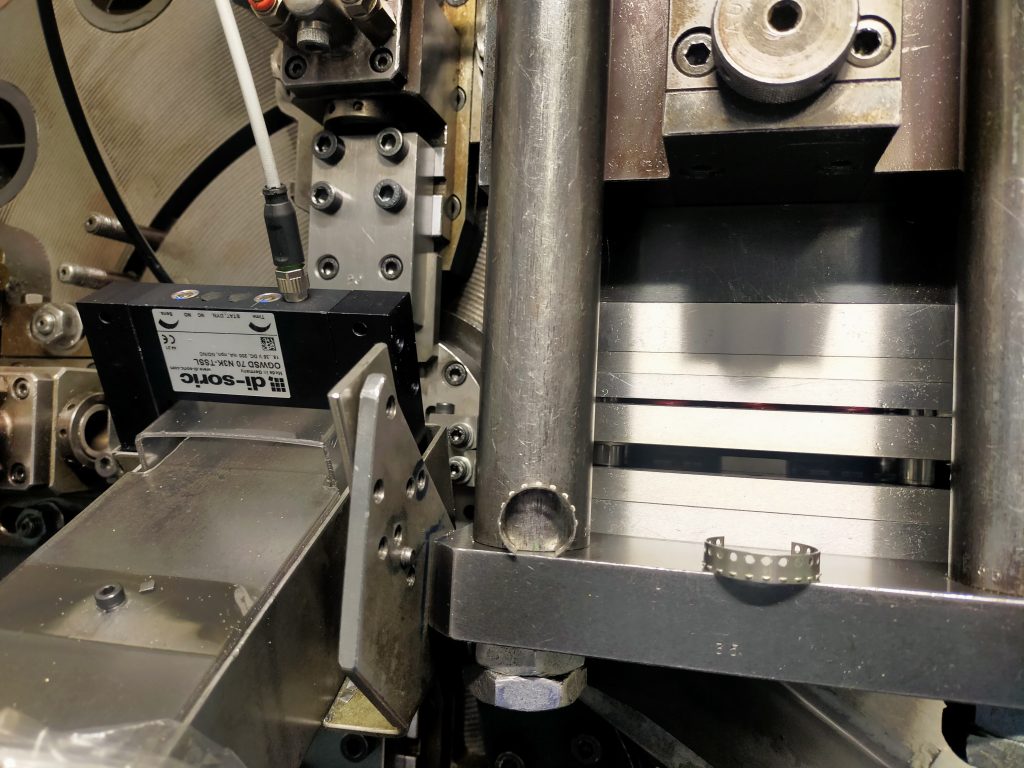

The precision metal small parts production department is equipped with the best machinery and systems on the market, capable of satisfying production and quality requirements for various industrial sectors.

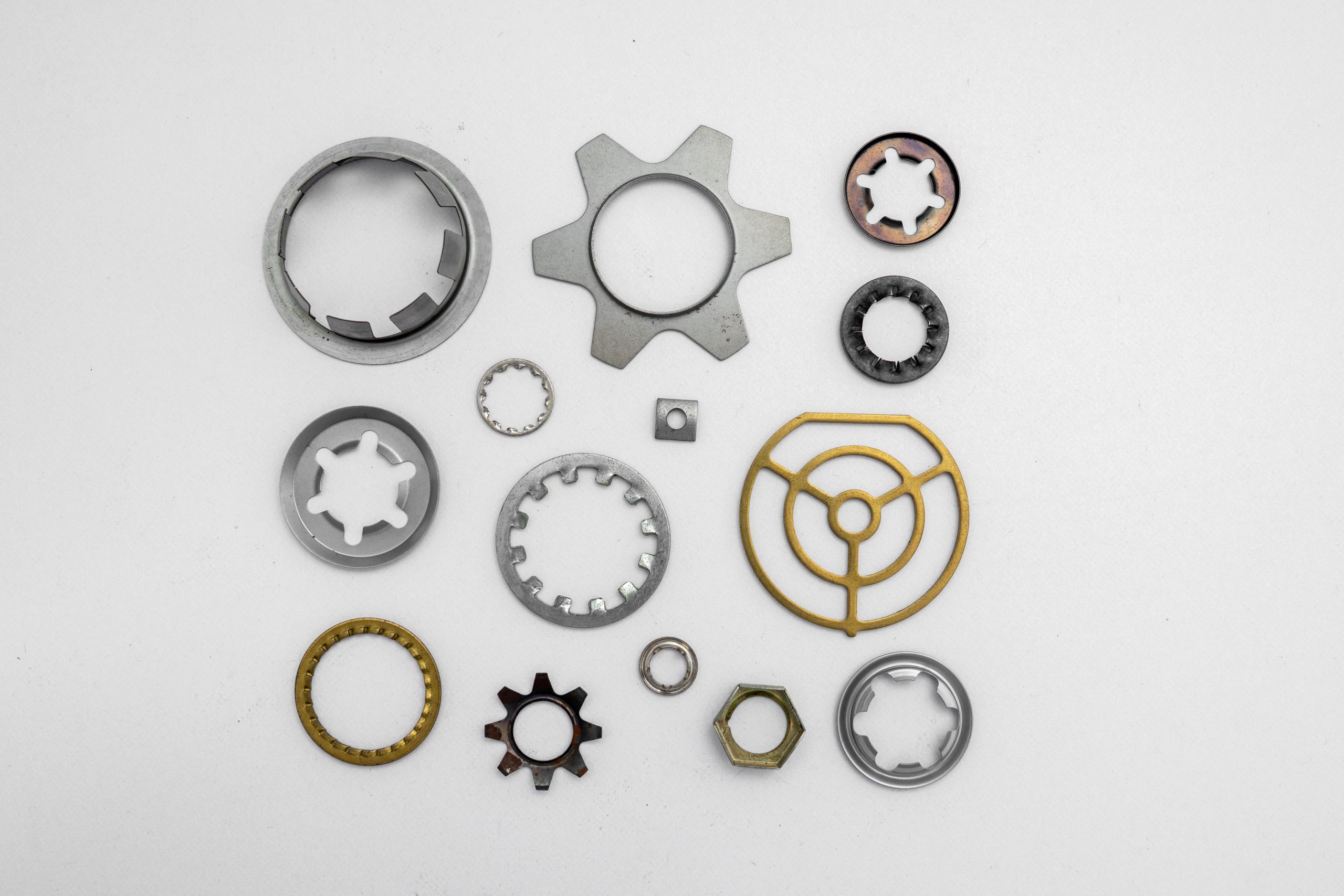

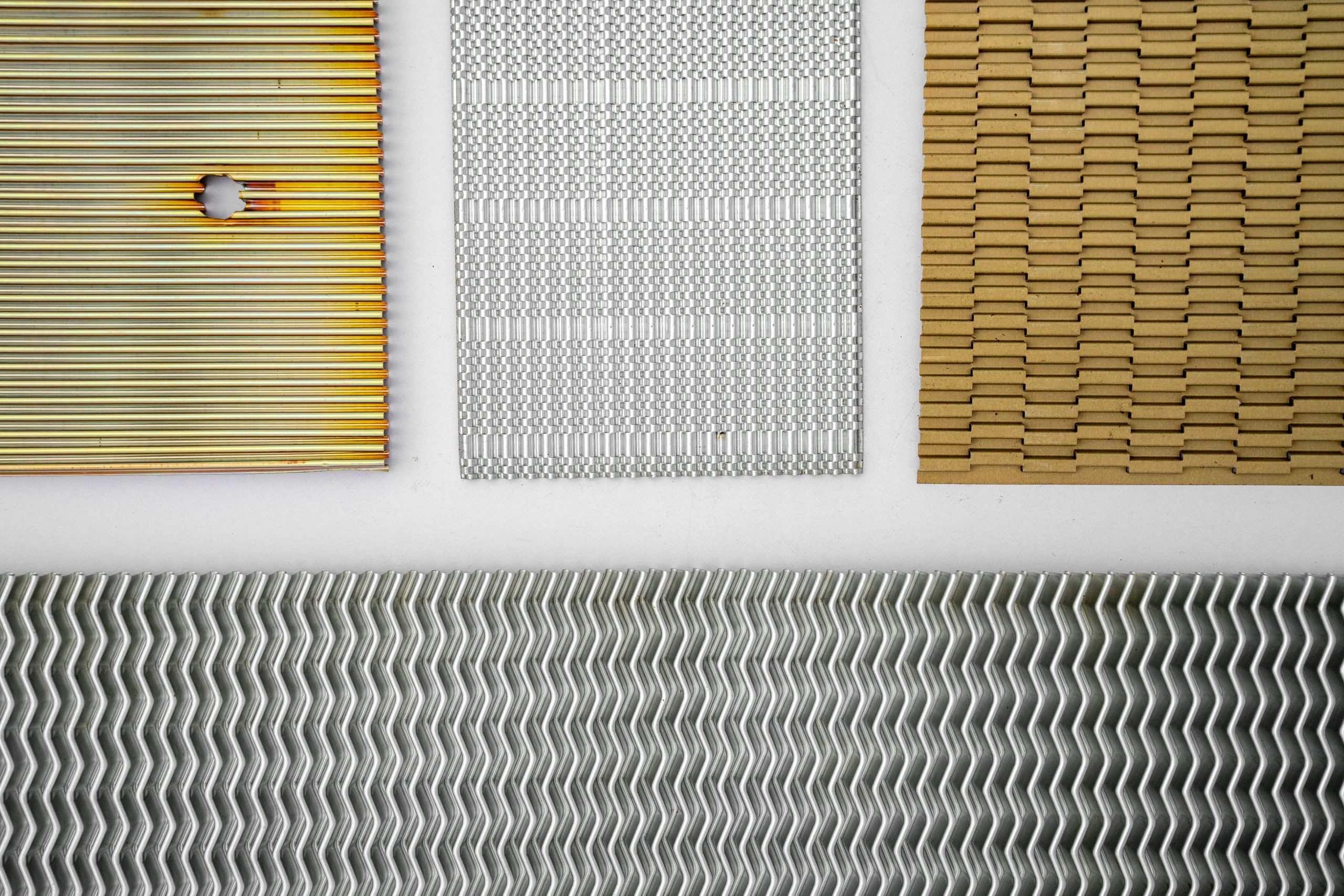

The production deals with the cold stamping of stamped and drawn parts, using materials such as steel, aluminum, iron, brass, copper, bronze and special alloys. Thanks to qualified and certified suppliers, we manage numerous surface treatments.

The maintenance of the molds is entrusted to the internal staff of the tooling department, which ensures continuous adjustments and improvements to optimize quality and productivity. All products are subjected to constant checks to ensure compliance with the standards agreed with the customer.

Mass production

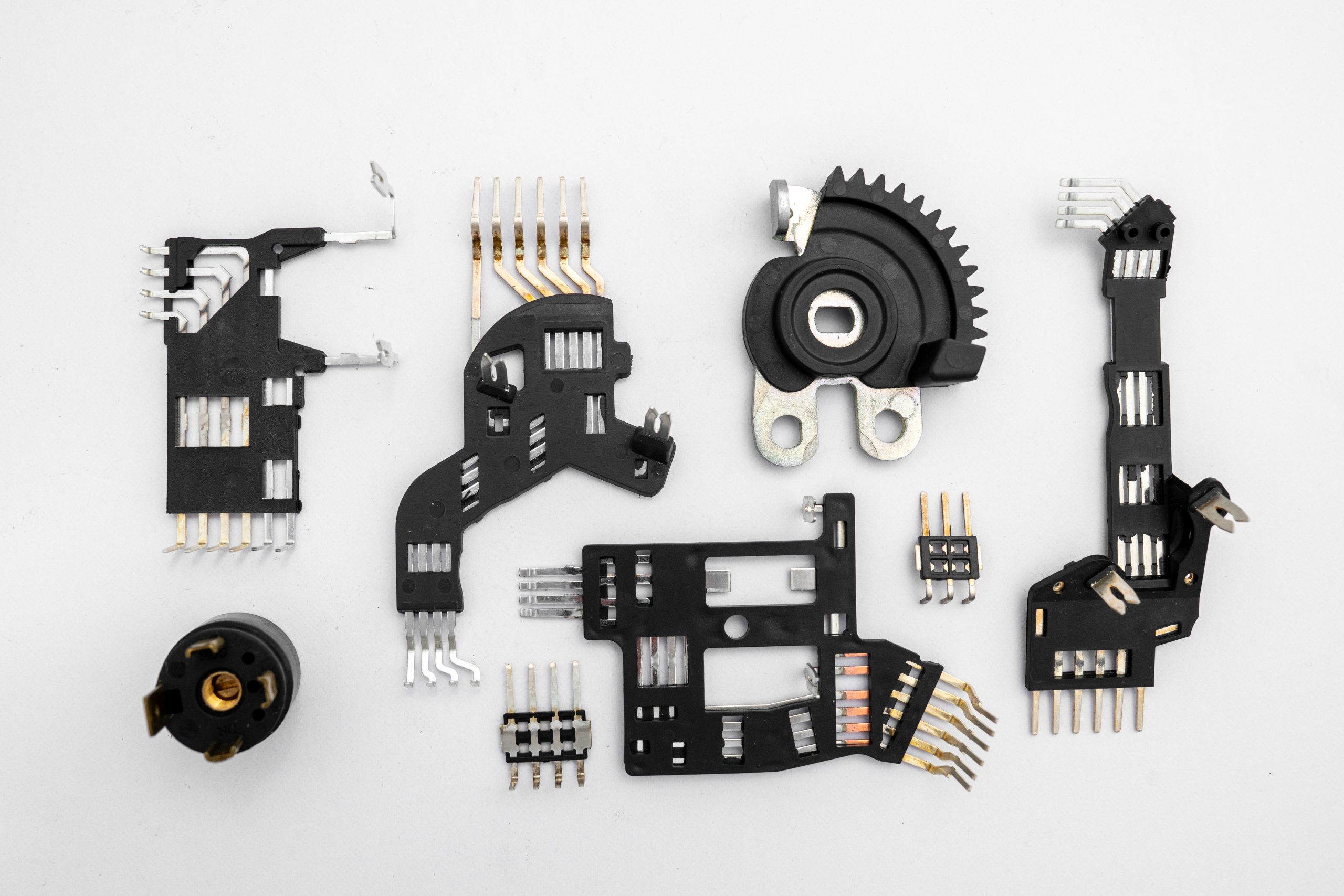

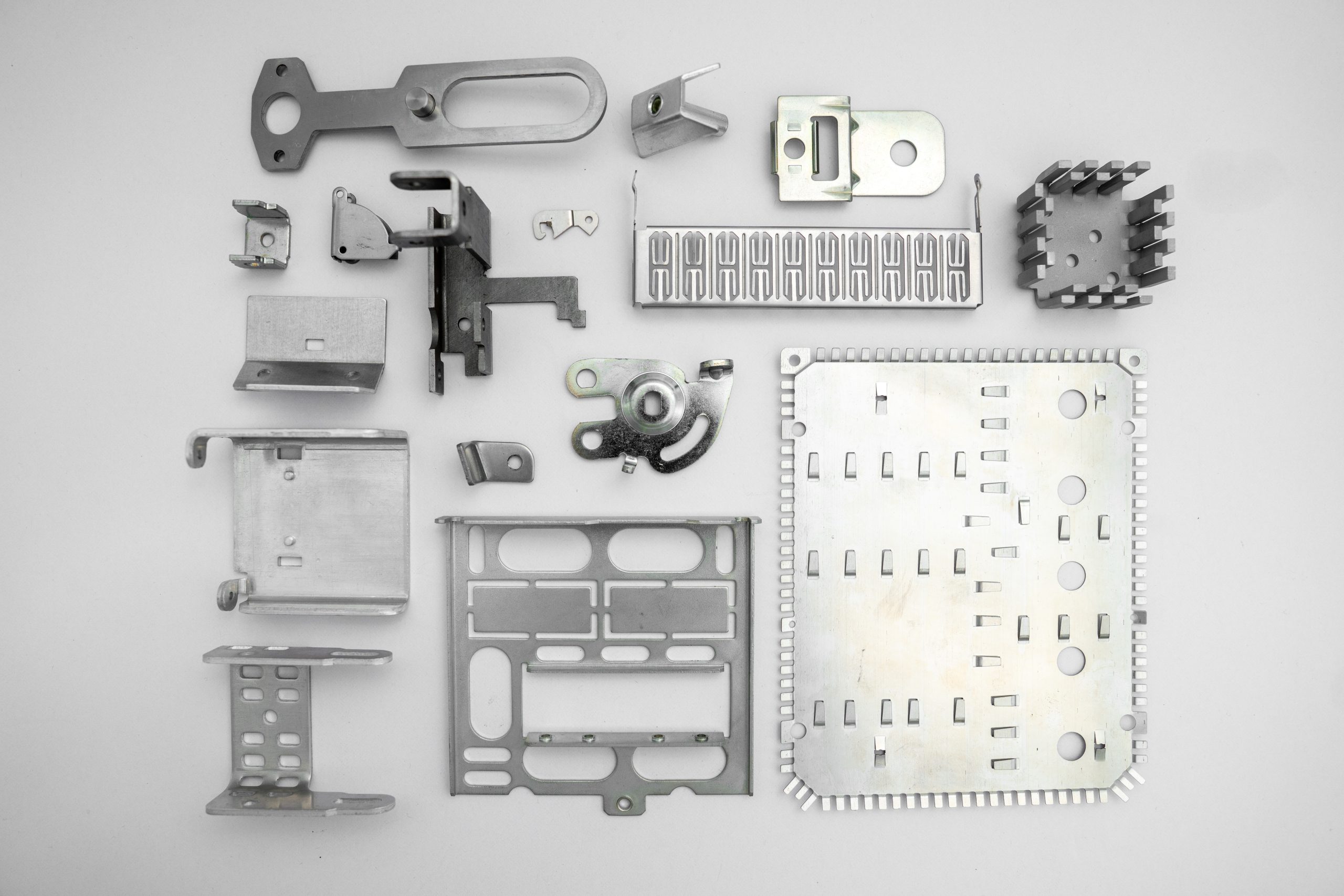

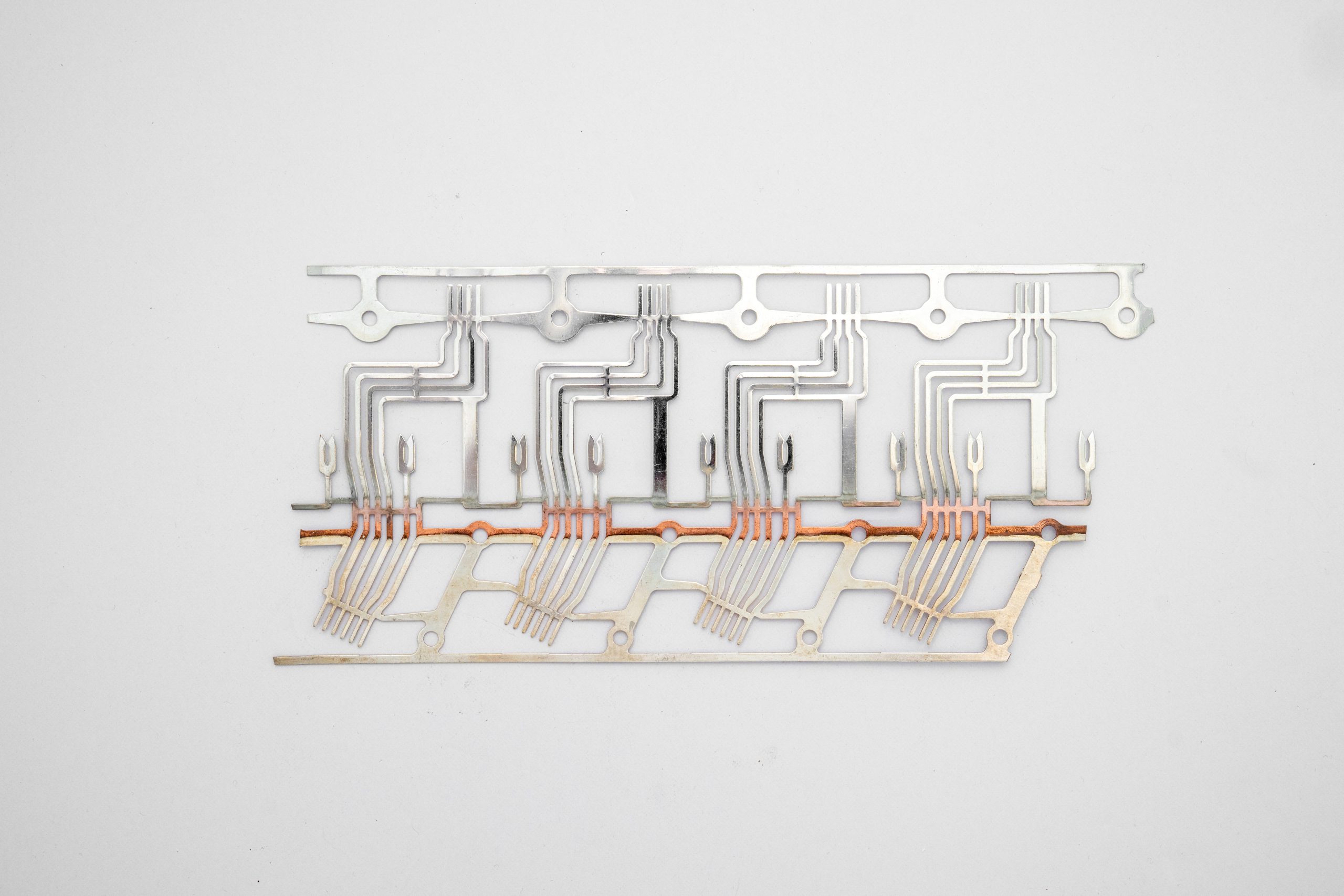

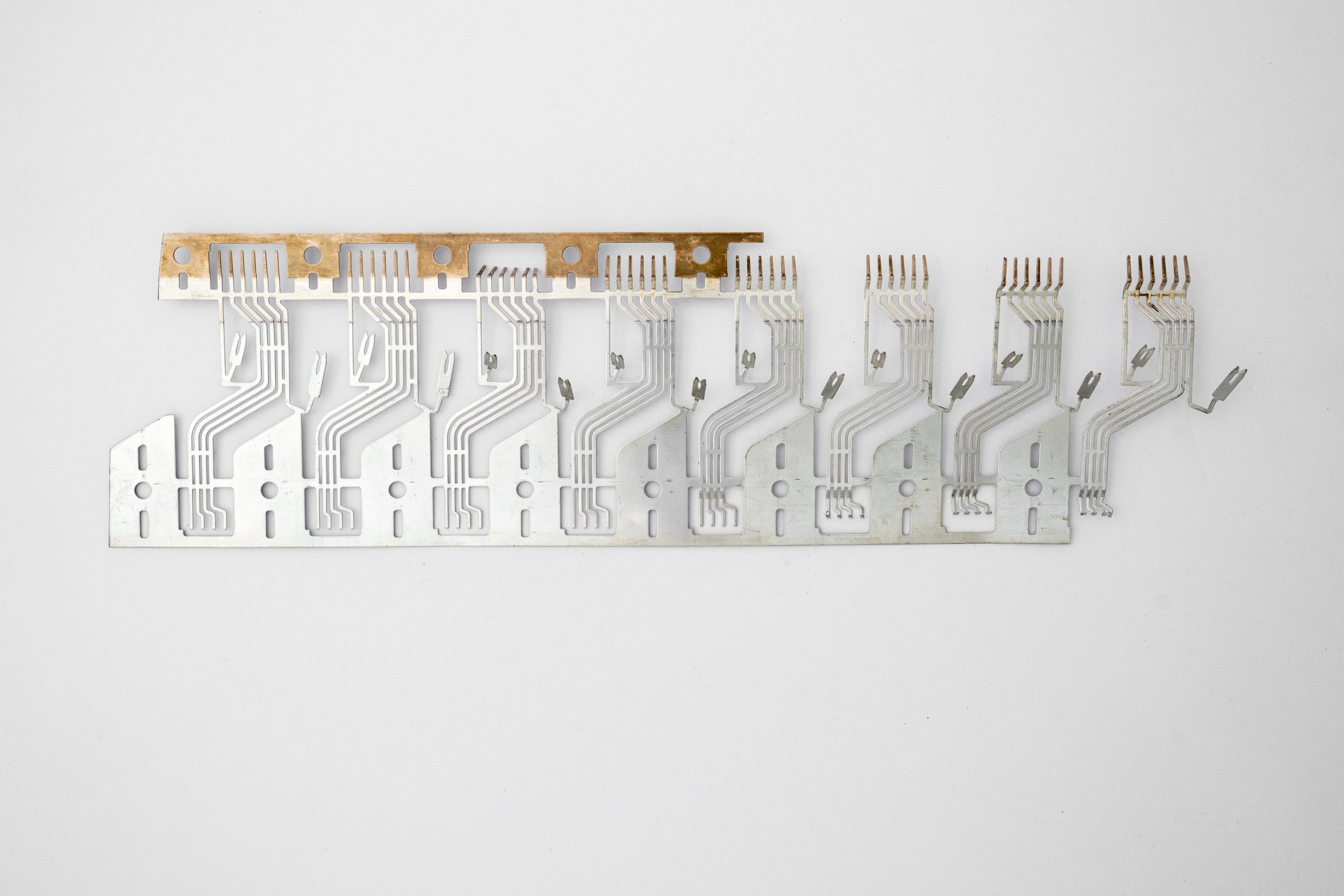

Our production departments specialize in the production and mass production of precision metal parts such as frames, electrical contacts, springs, clips, terminals, bus bars, and deep-drawn parts.

We produce small, medium, and large batches thanks to our wide range of machinery, ranging from 50 kN to 2000 kN, with speeds of up to 1800 strokes/min and mold loading dimensions up to 1400 mm in length.

Thanks to a modern, well-maintained machine fleet and automated industrial processes, we guarantee consistent quality and rapid delivery times.

Recovery and Assemblies

We offer a tailor-made service, integrating complementary processes to satisfy the multiple needs of customers:

- mechanical shooting

- welding

- tapping

- assembly

- other

Surface Treatments

We take care of the 360° production cycle of small metal parts and, using certified external suppliers, we manage numerous surface treatments based on the specific use of the finished product, such as:

- oxidation

- nickel plating

- gilding

- silvering

- galvanizing

- selective coatings

- temper

- discovery

- tumbling/vibratory finishing

- washing

Quality and Certifications

The company follows strict quality controls on the parts produced through procedures agreed with customers. The dedicated metrology room is equipped with cutting-edge measuring instruments to perform dimensional and functional checks.

We are an efficient organization certified ISO 9001, we guarantee product traceability and compliance with current regulations.

Our

Machinery Fleet

The company

About us

Mold Division

Mechanical processing

Production

Gallery

FAQ

Contact

Registered Office: Via A. Vivaldi 11,

20045 Lainate (MI)

Production Headquarters: Via G. Pergolesi 53,

20045 Lainate (MI)

Phone: 02 937 0779

Email: info@carlobazzi.it