Welcome to Carlo Bazzi’s FAQ section. Here you will find clear and detailed answers to the most common questions about molds and precision machining. Whether you’re looking for information on design, prototyping, manufacturing, or maintenance, you’ll find everything you need here to learn more about our services and understand how we can support you with tailored, high-performance solutions.

Molds and precision machining: Design and prototyping

What does Carlo Bazzi offer in mold design and precision machining?

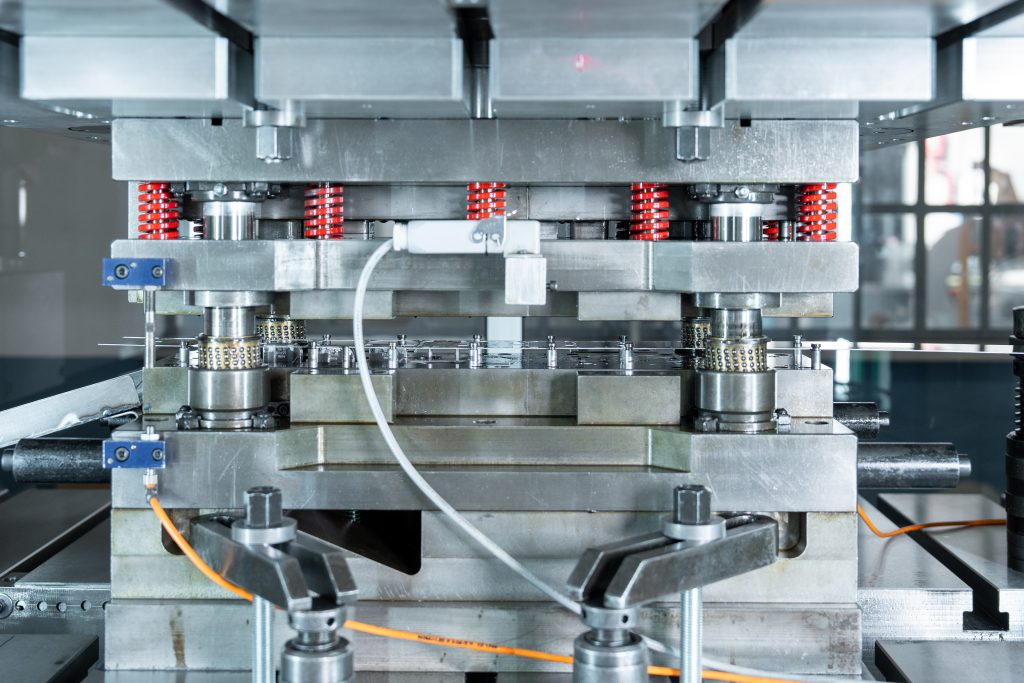

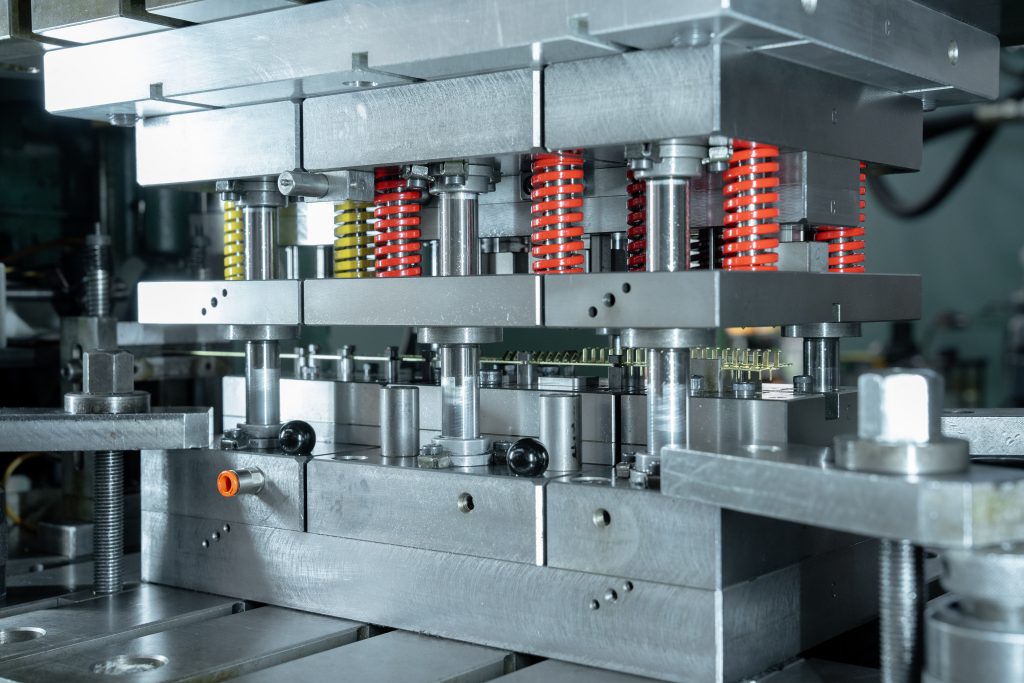

Carlo Bazzi designs progressive and block dies for stamping, bending and deep-drawing, using advanced CAD/CAM software to ensure accuracy and reliability.

Is it possible to make prototypes before mass production?

Yes, we offer a rapid prototyping service to test functionality and performance by simulating the real conditions of mass production.

Carlo Bazzi is in charge of mold maintenance?

Absolutely. We provide routine and extraordinary maintenance to ensure maximum durability and performance of existing molds.

Contract manufacturing and processing

What precision machining does Carlo Bazzi offer?

We offer contract machining with CNC machinery and precision technology: EDM, grinding, milling, turning, and more.

What materials are used for precision machining?

We machine steel, brass, aluminum, copper, bronze and special alloys, performing precision machining to customer specifications.

In what areas does Carlo Bazzi work?

We supply components for automotive, electronics, cosmetic, packaging, pharmaceutical, defense, aerospace and other high-precision industries.

What kind of machinery does Carlo Bazzi use?

Carlo Bazzi uses a fleet of high-quality machines to ensure results tailored to every production need. The main brands and technologies used include Faston, Bruderer, Bihler, Pressix, as well as traditional presses, fast presses, transfer presses and Bihler bending machines. These machines make it possible to handle complex machining with high repeatability, speed and consistent quality.